Regular analysis can extend the life of both fluid and system. Hydratech’s Fluid Monitoring Program (FMP) is a very straight forward, effective way to proactively monitor closed-loop system condition.

Founded in 1998, Hydratech begins life as a family run business formulating and manufacturing inhibited glycols, antifreeze solutions and water treatment chemicals.

Hydratech's mission and vision is to:

- Deliver products and services at competitive yet mutually sustainable prices – without compromising quality, service or safety.

- Formulate and manufacture durable heat transfer fluid solutions - capable of lasting >20 years.

- Invest heavily in research and development, to ensure Hydratech remain at the forefront of the heat transfer fluid industry.

- Build a quality workforce and provide local employment opportunities - attracting the very best talent and investing in employee training and development.

- Maintain significant stocks of raw and finished materials to ensure an ‘always in time’ delivery principle.

Hydratech begin to establish technical partnerships with those responsible for cooling and heating system design, installation, and operation - to improve efficiency, save energy and avoid costly downtime.

Coca-Cola, Haribo, Papa John’s Pizza, Walls, McCain, Ocado, BrewDog, Mercedes, BMW, Arla Dairies and Lidl are just some of the companies to start benefiting from the numerous operating advantages of Hydratech's specialist fluids.

Liquitherm achieves ISO-9001 accreditation - defining the company’s commitment to creating products and services in accordance with pre-defined standards. The certification has been renewed every year since.

Hydratech establish technical partnership with Kensa, the UK’s number one heat pump manufacturer. Hydratech’s Thermox heat pump antifreeze is utilized in thousands of Kensa’s commercial and domestic projects.

Hydratech Fluid Monitoring Program (FMP) was introduced for all heat transfer fluid customers. By taking a proactive approach to working fluid analysis, those responsible for managing or maintaining closed loop systems can detect issues early and take remedial action before fluid efficiency and system condition are compromised.

LTG launch DTX Glycol Hybrids – A range of heat transfer fluids, especially formulated for use in Process Cooling, Refrigeration, HVAC and Renewable Energy Systems - to exploit the advantages Ethylene Glycol has over Propylene Glycol, whilst delivering a non-toxic solution.

Coolflow DTX non-toxic heat transfer fluid is adopted by a host of well-known companies from the food and beverage sectors including, Hovis, DairyGold, Morrisons, Diageo, Thatchers Cider, Molson Coors, BrewDog, Eli Lilly and Co-op.

Thermox DTX introduced to heat pump market – representing a major step forward in heat transfer and pumping efficiency. Industry proven to deliver >10% improvement in COP, ROI and heat recovery when compared with Propylene Glycol based fluids. Adopters include Kensa, Ideal and Nu-Heat.

Arla Foods (UK’s largest dairy company) converts its Oakthorpe Dairy to Coolflow DTX.

Find out how Hydratech work in technical partnership with the dairy industry

BrewDog convert their flagship brewery in Ellon to Coolflow DTX, leading the way for many other major breweries including Beavertown, Camden Town and Tiny Rebel.

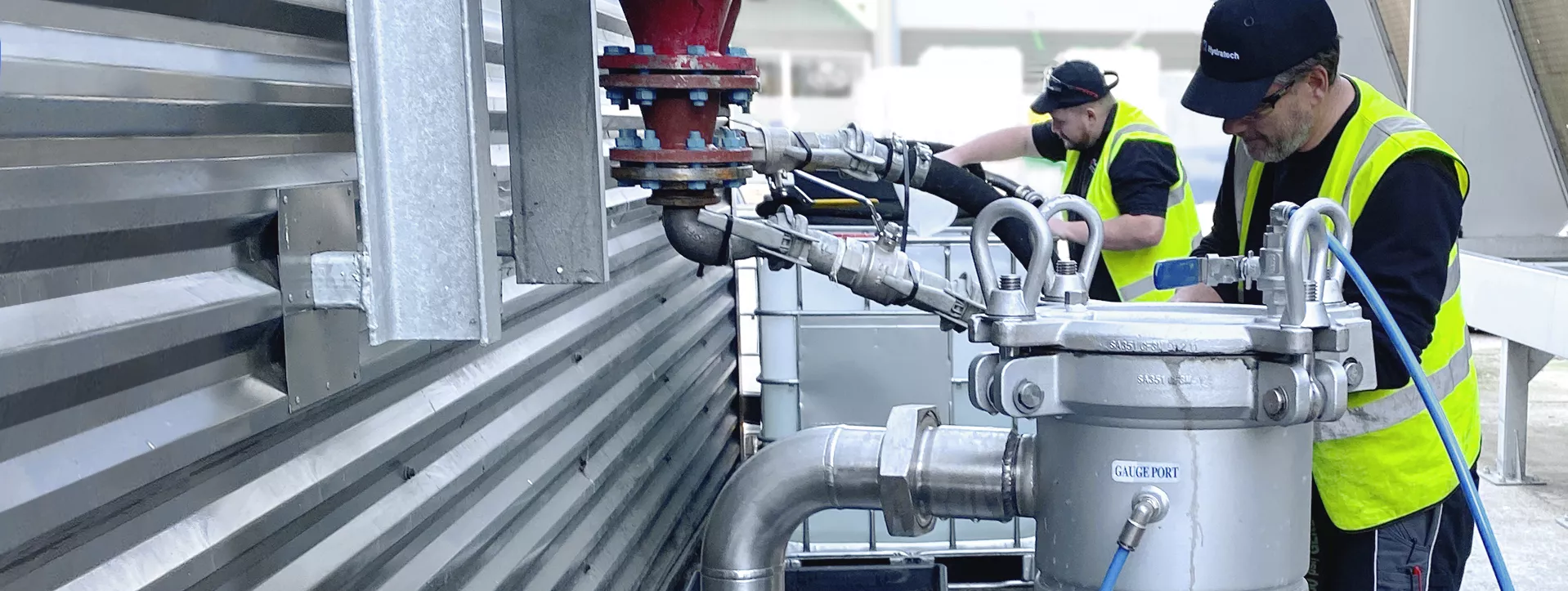

Hydratech Fluid Management Services (FMS) division is formed to provide specialist engineering and maintenance services to customers installing, commissioning, operating or optimising closed cooling and heating systems.

Hydratech Services establish technical partnership with Arla Aylesbury Dairy, to improve cooling efficiency and reduce energy costs. Work undertaken, including a switch to Coolflow DTX, reported a 17% reduction in energy consumed by the main coolant circulation pumps and process cooling systems. There was also a noticeable reduction in running time and load on their primary refrigerant compressors, which will considerably prolong the life span of their system.

Hydratech Services win contract for the Barclays Estate - Home for Barclays' technology, operations and functions teams across the UK. The contract is subsequently retained for 2020, 2021 and 2022. Work includes all aspects of HSE compliance for potable water.

UK world-class polar research ship – RRS Sir David Attenborough embarks on journey to Antarctica and the Arctic utilizing, Coolflow DTX to protect the vessel’s Heating and Chilled Water Systems, Refrigerated Cold Room and Fixed Fire Fighting System.

Hydratech Engineer brings ‘fluid thinking’ to Council - John Westerman, Sales Engineer at Hydratech has been voted onto the GSHPA (Ground Source Heat Pump Association) Council.

Hydratech join Cold Chain Federation and continue to grow technical partnerships with businesses throughout the temperature-controlled logistics industry – helping to provide precise, reliable, efficient cooling and significant energy savings.

Hydratech’s in-house lab conducts its 10,000th working fluid sample test and analysis.

Find out more about Hydratech's Fluid Monitoring Program (FMP)

Low Carbon Farming’s mega-greenhouse project in Norfolk and Suffolk, a world-first for renewable heating utilises Thermox DTX. Heat is extracted from the local water treatment works and transferred in a closed loop system, to the heat pumps located at the greenhouses. The project, capable of producing 12% of the UK’s tomatoes with a 75% reduction in carbon footprint, demonstrate how renewable heating systems, and heat pumps in particular can be deployed at a commercial scale.

Hydratech continue to set the standard with further ISO accreditations. ISO 14001: 25 and 45001:2018 are added to the existing 9001:2015 qualifications.

Hydratech launch new website. The completely redesigned site provides a user-friendly experience, with navigation and functionality being the focus, underpinned by a narrative that reflects the company’s technical expertise, experience and consultative approach to heating and cooling system optimisation.

Hydratech develop Safeguard range to reduce drain down and winter layup costs. The non-toxic winterization solution provides high-performance, low-cost freeze protection for caravan, motorhome and marine craft wastewater and hydronic heating systems.

Hydratech expands into U.S. Located in Windsor Locks, Connecticut, the new production facility and office space has enabled Hydratech to introduce their industry proven products and services to the American RAC, HVAC and renewables markets, as well as developing their existing relationships with the likes of Coca-Cola, PepsiCo, Papa John’s and Haribo.

The ED&F (Engineering, Design, and Fabrication) Division is added to the Hydratech Services portfolio, offering customers a bespoke Engineering, Design and Fabrication solution for all closed loop cooling and heating systems. From side-stream filtration units to building corrosion coupon rigs, the ED&F Division provides a range of specialist services to help improve the performance, efficiency, and reliability of closed water systems.

Combining expertise in mechanical engineering, manufacturing and fluid management, the division is fully qualified and accredited to meet all the necessary welder codings for stainless-steel and structural-steel fabrications, as well as a host of AutoCAD seats to design and test R&D projects, prior to manufacture.

Hydratech demonstrate their commitment to health & safety, sustainability and ESG (environmental, social and corporate governance), by achieving the nationally recognised and respected SafeContractor Accreditation. The UK’s leading accreditation scheme assures customers that a business meets all the standards and regulations they require - proving even more credibly that a business is safe, stable and ethical.

Hydratech Spain is launched! With a new manufacturing plant, industrial warehouse, and corporate office in Gavá - Barcelona, Hydratech ES is in the perfect position to take process cooling and renewable energy system efficiency to the next level on the Iberian Peninsula.